October 7, 2024

The 65-ton (60-metric ton) 65|RT is the newest edition to Link Belt Cranes’ proud Rough Terrain product line, taking over from the ultrareliable and long-established RTC-8065 Series II. The all-new 65|RT includes a four-section full-power greaseless main boom (38–115 feet [11.6–35 meters]) and an optional 35–58-foot (10.7–17.7-meter) offsetable bi-fold lattice fly that are manufactured in the United States at Link-Belt’s headquarters in Lexington, Kentucky.

Along with this, the 65|RT brings several impressive enhancements to the table. It features a new hydraulic boom extend system, allowing for easier service and greater reliability, as well as LED lighting for brighter, more efficient lighting during low-light conditions.

The all-new 65|RT transports under 92,000 pounds with counterweight installed.

The 65|RT includes our latest appearance package, featuring a new steel deck and sheet metal with textured paint for anti-slip surfaces. It is also equipped with a new six-speed Dana transmission with a remote filter for ease of servicing. The transmission is mounted to a 270-horsepower Cummins QSB6.7L Tier 4 engine.

The 65|RT features a maximum tip height of 211.6 feet with attachments.

The crane’s ergonomic operator’s cab includes extra-large windows, time-delayed wipers, a Bluetooth AM/FM radio integrated with a NOAA weather radio, an internal-rated capacity limiter light bar, and single- or dual-axis hydraulic controllers. Per the Link-Belt Vision Package, cameras for winch, swing, and reverse views are standard. Additionally, all gauges and switches are backlit to maximize visibility in low light, and the 65|RT includes a Confined Area Lifting Capacities (CALC) system for assistance in tight, confined operating spaces.

Job site travel with the 65|RT is smooth thanks to Link-Belt’s greaseless four-link suspension. Its optional hydro-gas suspension system makes for an unmatched job site travel experience, offering smooth, comfortable travel across any job site. This paired with the crane’s remote-mounted transmission oil, engine oil, fuel filters, CANBUS diagnostic network, serviceable pontoons, and grease-free main boom makes service and maintenance more simple and cost-effective than ever before.

“Overall, the 65|RT offers a new level of reliability and performance with the same level of precise control and capacity for which our customers have become accustomed,” said Link-Belt Rough Terrain Cranes Product Manager Kelly Fiechter. “The changes are a reflection of current industry standards with many of these new features also found on other rough terrain cranes in our product line.”

Fiechter added that the 65|RT is a great crane for almost any scope of work, stating that its job site mobility and supreme transportability allow it to be hauled to nearly any job site in one piece ready to work, making it a very user-friendly machine. One that fits perfectly in Link-Belt’s modern, industry-leading fleet.

Tags

- 175|AT

- Aftermarket

- all-terrain

- autograde

- avetta

- Berco

- Best Managed Companies

- bushings

- Canada's Best Managed Companies

- Case Studies

- Caterpillar

- construction

- continuous improvement

- crane

- cranes

- crusherwearparts

- customer focused

- Deere

- dozer

- dozerblades

- efficient

- environment

- EQUIPMENTWATCH

- Esco

- ESS

- excavator

- Excavator Crawler Medium

- excavator telematics

- face sheild

- FINAL TIER 4 ENGINES

- fire

- fire safety

- FUEL CONSUMPTION

- fuel efficiency

- fuelconsumption

- fuelefficiency

- gnss

- gps

- grade

- grade control

- headandcoldstress

- healthandsafety

- healthandsafetyexcellence

- Heavy Equipment

- heavy lifting

- heavyequipment parts

- heavymachinery

- HEAVYMACHINERY TOOLS

- hybrid

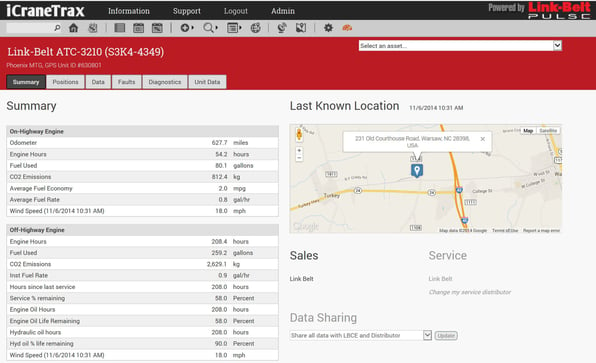

- iCraneTrax

- idler

- imc2.0

- Intelligent Machines

- isn

- ITM

- jobsite

- jobsites

- johndeere

- Komatsu

- Komatsu Dozer

- Komatsu Excavator

- Lattice

- LBX

- lifting

- link belt excavator

- Link-Belt 245 X4 Spin Ace

- Link-Belt Cranes is Pulse 2.0

- linkbelt

- LINKBELTCRANES

- links

- loader

- loaderlips

- lockout and tagout

- loto

- machine

- machinecontrol

- maintenance

- my komatsu

- new excavator

- OEM

- pipe

- predictive maintenance

- preventionofslipsandfalls

- remote care

- rigging

- safestemployers

- safety

- safety glasses

- safety talk

- safetyandeyecontact

- safetyandharness

- safetyatheights

- safetycompliance

- safetyfirst

- safetyhandsignals

- safetyspotting

- safetytalks

- sitech

- slipsandfalls

- smart construction

- SMART QUARRY

- smartconstruction

- telematics

- tier4

- TOOLSAFETY

- topcon

- trackshoes

- trimble

- undercarraige

- undercarriage

- vises

- Volvo

- weir

- wheel loader

- WRENCH

- wsib

SIMILAR BLOGS

Unveiling the Specifications of the Link-Belt 175 AT Crane

Link-Belt Telematics

POST YOUR COMMENT