Spotter Safety Talk

While spotting for heavy equipment operators may not seem like a dangerous task, it certainly is. Every year back-over incidents between equipment and spotters result in fatalities. OSHA states that dump trucks followed by semi-trucks and ordinary pickups are responsible for the majority of backover incidents in the past 10 years on the job.

Spotting for equipment has been proven to be an effective safeguard for preventing incidents between pedestrians and the equipment as well as preventing property loss incidents, but safe work practices need to be established to protect spotters as well.

Basic Safe Work Practices for Spotting

- Never walk behind the equipment and spot at the same time. When spotting, stand at the desired area where the equipment is going and flag the equipment back to you.

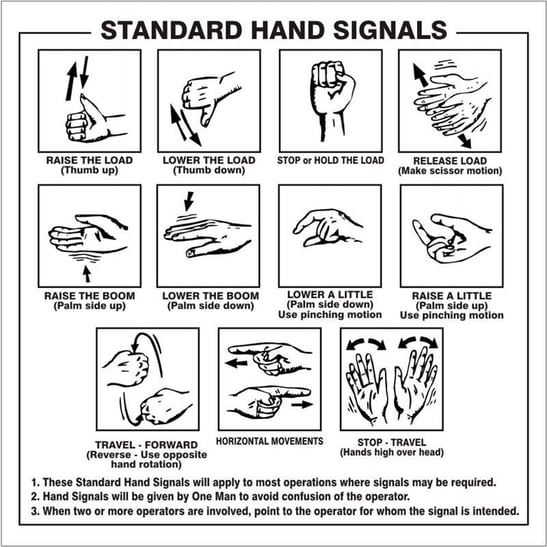

- Agree on hand signals prior to any spotting activities with equipment operators.

- As the operator, stop anytime you lose sight of the spotter.

- Review the work area for any additional hazards such as trip hazards that a spotter or other ground personnel could trip over. Or evaluate the work area for fixed objects that the equipment can strike. Remove any people, objects, or equipment prior to spotting equipment in or out of an area to eliminate the possibility of a strike.

Other Tips for Spotting

When planning work, look at the task and determine if there is a way to eliminate backing or minimize it. If there are trucks in the work area that need to dump material, look to be able to pull through where they need to dump. If pulling through is not possible, pick a route that minimizes the need to back up.

Oftentimes, personnel who are spotting for equipment may not have ever operated that specific piece or model of equipment. Work with operators to discuss and review the blind spots of the equipment onsite. Some of the large off-road dump trucks have more than a 60-foot blind spot in the rear. If the spotter or other personnel in the work area are not aware of the blind spots of the equipment, they may unknowingly walk into the line of fire.

Signaling Techniques

Proper signaling can greatly increase the efficiency and productivity of a construction project whether it is guiding a delivery vehicle, a forklift, or a crane. Improper signaling can kill or injure workers as well as cause severe property damage to a project. The following points are recommended discussion points when discussing signaling.

Guide for Discussion

Know the signals. If you must, get with the operator and coordinate what signals mean. Allow only one person to give signals. Be sure the operator knows who the signal person is.

The signal person must:

- Always be in a position to see both the operator and the work area.

- Always watch the load; the operator must watch the signal person.

- Not move a suspended load over workers.

- Always warn workers when loads are being moved in their area.

- Watch for overhead power lines and any other obstructions.

- Remember the proper type of signaling operation – for a truck, forklift, or crane.

Remember!

It only takes one small mistake on the part of the signal person to cause a severe injury or major property damage. Make sure you and the operator understand each other and the signals to be used.